Cisco Meraki infrastructure with airista’s angle of arrival technology creates an edge platform to push sensor fusion analysis closer to production

Hannover Messe was held last week in Germany. The event is one of the world’s largest industrial trade shows. The event typically draws 6,500 exhibitors and 250,000 visitors. However, this year attendance was anecdotally 80,000. Asian vendors who typically occupy 30% of the space, did not attend. And there was little foot traffic from visitors outside of Europe.

Vendors with demos that highlight sensor fusion continued to be a major theme. As production processes get more sophisticated, combinations of sensor inputs are increasing efficiency, improving quality, and adding depth to the production record of each digital twin.

AiRISTA was invited to participate in Cisco System’s booth. Cisco’s presence has come a long way in a few short years. This year’s booth was a large island with 2 floors. AiRISTA’s corner kiosk in an area that represented manufacturing supply chain solutions.

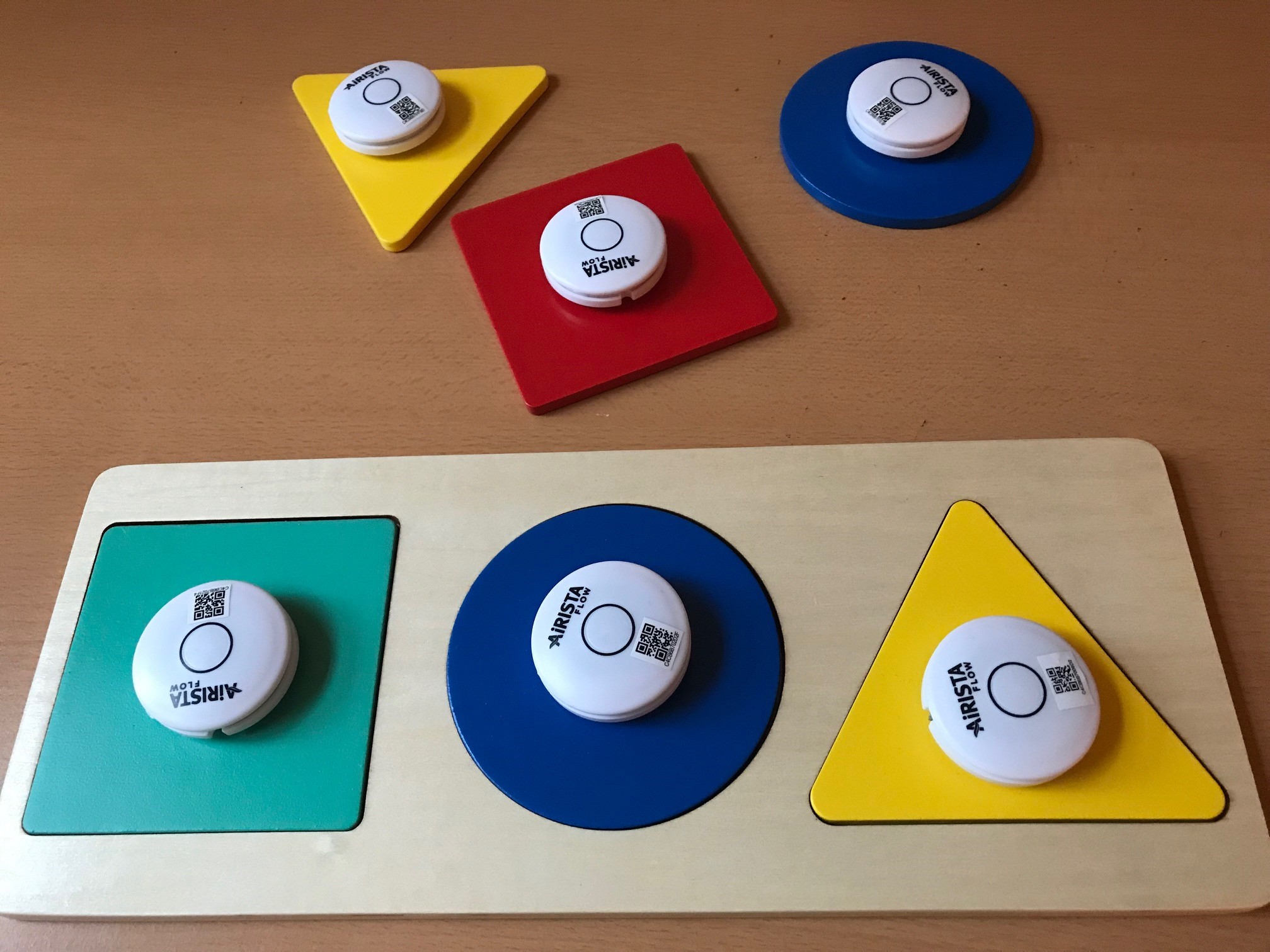

The AiRISTA demo combined submeter location accuracy and computer vision from an ecosystem partner, Cogniac. Leveraging Cisco Meraki’s wireless infrastructure and video cameras, the demo used wooden puzzle pieces to illustrate component delivery and QA inspection.

Leveraging Cisco Meraki’s wireless infrastructure and video cameras, the demo used wooden puzzle pieces to illustrate component delivery and QA inspection.

Using the AiRISTA BLE gateway with with support for angle of arrival, each puzzle piece was tracked to within 20cm of accuracy as they were moved across the kiosk shelf. Corresponding movement was updated by the second on the display’s map of the shelf top. Each move of a puzzle piece was reflected in production metrics including finished goods, count against quota, remaining inventory, and takt time.

The dashboard also alerted to puzzle pieces that represent a “defect”. In this case, a red square puzzle piece was flagged as an error by the Cogniac software running on the Meraki camera. Cogniac has introduced a new paradigm for training video AI models. To create the AI module that runs on the camera, we took a series of still images of puzzle pieces in various positions. Once uploaded to the Cogniac cloud, we distinguished “good” pieces from “bad”. The Cogniac algorithms produce a model that, when pushed to the camera, draws a green box around good puzzles pieces and a red box around bad pieces. The modeling process took less than a day and its resolution continues to improve as more images are fed to the cloud based algorithm.

{% video_player “embed_player” overrideable=False, type=’hsvideo2′, hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=False, hidden_controls=False, loop=False, muted=False, full_width=False, width=’1500′, height=’843′, player_id=’75756553338′, style=” %}

This fusion of submeter location accuracy and video based defect detection solves a variety of hard problems in manufacturing. For example, engineered to order (ETO) production cells must ensure the right components are at the work cell at the right time as the next unit of production arrives. Any components that are missing can be flagged in advance and quickly brough to the cell. Combined with video AI, visual defects in the parts can be caught before they are assembled avoiding expensive rework. One visitor to the booth, an Italian manufacturer of drones, said this type of system could increase efficiency and reduce waste as pre-preg material is cut and laid on forms before curing in autoclaves. Another manufacturer of fork trucks said component mistakes have led to penalty payments due to missed deadlines – in one case, shipping a single fork truck via FedEx to Australia!

According to Gartner®, “The need for real-time insights and localized action, regulatory requirements, network constraints, and volume and velocity of data generated from sensors and endpoints are forcing I&O leaders to deploy edge computing solutions in order to process data closer to the source of generation.”[1] With platform components already at the network edge, infrastructure vendors like Cisco Meraki are in a prime position to host these intelligent edge components for faster and more scalable deployment of sensor fusion solutions. Gartner goes on to recommend customers “deploy an edge computing solution that is modular, is scalable, is easy to manage and can accommodate additional use cases with minimum additional investments”.

[1] Gartner, “Market Guide for Edge Computing Solutions for Industrial IoT”, Santhosh Rao, December 18, 2020