RFID and RTLS tags for inventory improve how businesses track and manage inventory in real time. They enhance accuracy across the supply chain and reduce labor costs. This article explains how these technologies work, their benefits, challenges, and implementation strategies for effective inventory management.

Key Takeaways

RFID and RTLS technologies significantly enhance inventory management through real-time tracking and improved inventory data accuracy, with RFID offering automated data capture and RTLS ensuring precise location tracking.

While RFID typically has lower initial costs and higher accuracy for asset tracking, RTLS provides more precise real-time location data, choosing between the two depends on specific industry needs and budget considerations. Often RFID and RTLS are deployed together and provide synergistic value.

Successful implementation of RFID and RTLS systems requires careful planning, selection of suitable tags and readers, and ongoing maintenance to ensure optimal performance and operational efficiency.

Understanding RFID Technology for Inventory Management

Radio frequency identification technology focuses on the identification and data capture of assets, transforming inventory management through real-time monitoring of stock levels and movements. It offers significant advantages over traditional barcode systems, including greater efficiency, speed, and accuracy in inventory management across various industries. Passive RFID systems consist of essential components such as an RFID reader and a passive RFID tag that work together seamlessly, enhancing RFID tracking capabilities.

Unlike active RFID tags, passive RFID tags do not have an internal power source and rely on the energy emitted by RFID readers for communication and identification purposes.

These systems operate at various frequencies, including low frequency (LF), high frequency (HF), and ultra-high frequency (UHF), each affecting their applications and performance. RFID technology offers faster processing and greater accuracy compared to traditional barcodes due to its non-line-of-sight scanning capability.

Benefits of Using RFID Tags

Radio frequency identification (RFID) offers significant advantages over traditional barcode systems, providing greater efficiency, speed, and accuracy in inventory management. The key benefits of RFID technology are numerous and impactful. A major advantage is the increased accuracy in inventory tracking, which can improve from 63% to 95% with RFID implementation. This technology automates data capture, providing real-time updates that significantly enhance asset visibility and reduce losses associated with misplaced or stolen items. RFID tags also remove the need for line-of-sight scanning, speeding up inventory processing and lowering labor costs. Additionally, data from multiple RFID tags can be collected and stored simultaneously without the need for line-of-sight, contrasting with barcode scanning which requires manual one-by-one scanning, increasing the potential for errors.

Another crucial benefit is the ability to track returnable assets, which can further enhance visibility and reduce losses. Overall, numerous organizations leveraging RFID technology have reported significant improvements in inventory accuracy and operational efficiency, making it a powerful tool for modern inventory management.

Challenges in Implementing RFID Systems

Despite its many benefits, implementing RFID systems comes with its own set of challenges. One of the primary obstacles is the cost associated with the technology. Initial expenses for RFID services can be significant, including hardware costs, which can be substantial. Each physical point where identification is to be read requires its reader device. Additionally, environmental factors such as metal surfaces can interfere with radio waves, reducing the read range and performance of RFID tags.

Another significant challenge is the resource-intensive nature of setting up an RFID system. This process requires careful planning and integration with existing systems, which can be time-consuming and complex.

Despite these challenges, the long-term benefits of RFID technology often outweigh the initial hurdles, making it a worthwhile investment for many businesses.

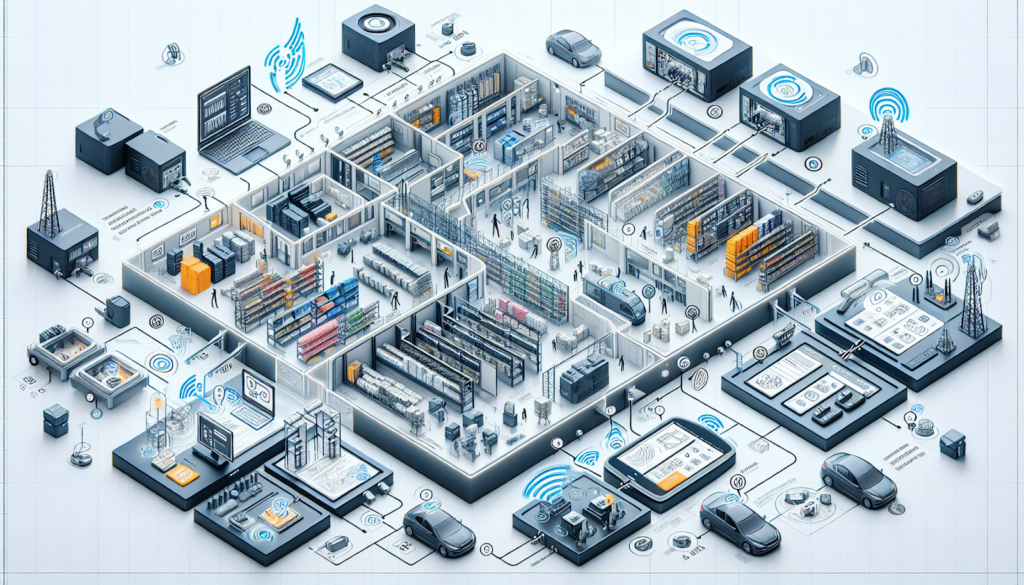

Exploring RTLS Technology for Inventory Management

RTLS technology goes a step further by using tags and sensors to provide real-time location systems data for effective inventory management. This technology leverages various methods such as Wi-Fi, Bluetooth, UWB, RFID, and GNSS to determine the exact location of assets.

By calculating the position of tagged items based on signal strength, time of flight, or trilateration, RTLS ensures precise tracking and improved supply chain management.

Advantages of RTLS in Inventory Management

RTLS technology offers several advantages that can significantly enhance inventory management. For instance, hospitals employing RTLS can track the location and status of medical equipment in real time, leading to improved operational efficiency. This capability is crucial in healthcare settings where timely access to equipment can directly impact patient care.

RTLS applications extend beyond healthcare, enhancing asset visibility across various industries. Organizations can quickly locate and utilize their inventory, leading to better resource allocation and reduced operational costs. The real-time tracking capability of RTLS ensures that businesses have up-to-date information on their assets, facilitating smoother operations.

Potential Drawbacks of RTLS Systems

While RTLS technologies offer impressive benefits, they also come with potential drawbacks. One major issue is accuracy, which can be compromised due to interference or obstructions, leading to erroneous readings and missed signals. Additionally, the initial setup costs for RTLS can be significant, requiring investment in hardware, software, and installation services. For more details on the costs associated with RTLS, you can refer to this article.

Technology advancements allow RTLS solutions based on Bluetooth Low Energy (BLE) can provide improved accuracy. New BLE technology including Angle of Arrival and High Accuracy Distance Measurement provide location accuracy to less than one meter. This high level of accuracy might be most appropriate in specific areas like supply rooms and receiving docks. These technologies provide the additional benefit of tracking location in the vertical dimension, providing the location for items on shelves for example.

Despite these challenges, the benefits of RTLS often justify the investment, particularly for organizations that require precise location tracking.

Comparing RFID and RTLS for Inventory Tracking

When it comes to inventory tracking, both RFID and RTLS technologies have their unique strengths and applications. RFID technology prioritizes identification and data capture, making it highly effective for inventory management. Radio frequency identification provides greater efficiency, speed, and accuracy in inventory management across various industries, while also differentiating its applications and benefits compared to other technologies like RTLS and NFC. On the other hand, RTLS emphasizes accurate real-time location tracking, which is crucial for industries that require precise asset tracking within centimeters or meters.

Businesses should consider their specific needs, such as the desired level of location accuracy and budget when considering the best application for each of these technologies.

Accuracy and Precision

In terms of accuracy and precision, RTLS generally delivers more precise asset location data compared to RFID, which can vary based on environmental factors. RFID tags, particularly those used on metal surfaces, can face performance issues due to signal interference. However, where RFID technology provides insight into the last known location near a reader device, RTLS enables improved asset utilization by providing up-to-date location data in real-time on each asset, facilitating informed resource allocation.

Real-time intelligence enabled by RFID allows for improved decision-making across various sectors, transforming operational processes. The choice between RFID and RTLS for accuracy and precision should be based on the specific requirements of the business and the environment in which the technology will be used.

Cost and Budget Considerations

Cost is a critical factor when deciding between RFID and RTLS systems. RFID systems tend to have lower initial implementation costs compared to RTLS systems. However, the costs associated with RFID technology are still significantly higher than those for traditional barcode systems.

Implementing RTLS across the entire facility involves higher costs, particularly due to the investment in infrastructure and technology needed to support the system. Both RFID and RTLS should be evaluated for their overall budget implications, considering both short-term and long-term cost factors.

Businesses must weigh these costs against the benefits of improved inventory tracking capabilities.

Industry-Specific Applications

Different industries utilize RFID and RTLS technologies to address their unique challenges and enhance operational efficiency. For instance, certain apparel brands have seen inventory accuracy improve and stock discrepancies reduced by over 95% with RFID tags. AI can analyze RFID data to predict inventory needs and optimize supply chain processes, further enhancing operational efficiency.

In healthcare, RTLS applications facilitate asset tracking and monitoring of staff and patients, leading to improved operational efficiency. Predictive analytics derived from RFID data can assist businesses in anticipating supply chain disruptions, ensuring smoother operations and better resource allocation.

Implementing RFID and RTLS Systems

Implementing RFID and RTLS systems requires a detailed assessment of current operations and technological needs. Successful implementation involves understanding organizational needs, selecting appropriate technology, and developing a comprehensive implementation plan.

RFID tags can be used for real-time updates and data writing, enhancing inventory management and operational efficiency. RTLS solutions further ensure accurate item availability at the right time and location.

Selecting the Right Tags and Readers

Choosing the right RFID tags and readers is crucial for effective inventory tracking. Factors like environmental conditions, specific requirements, and tag durability should be considered. The design and certification of RFID tags must align with the intended application to ensure optimal performance.

Identifying business requirements and choosing suitable tags and readers are crucial steps in setting up an RFID system.

Setting Up the System

Setting up an RFID or RTLS system involves essential steps like site assessment, hardware installation, and software integration. The complexity of setting up these systems may pose challenges, requiring specialized knowledge for installation and maintenance.

Key steps for setup include selecting appropriate hardware, installing equipment, configuring software, and integrating with existing systems.

Maintaining and Troubleshooting

Maintaining RFID and RTLS systems is crucial. It helps to troubleshoot and ensures optimal performance and accuracy. Regular maintenance, performance monitoring, and quick troubleshooting are key practices for maintaining these systems. Unlike most RFID tags, RTLS tags require battery replacement which should be considered as part of the regular system maintenance. Regular checks and updates help address any operational issues promptly, enhancing the overall efficiency of the system.

Applications of RFID and RTLS Technologies

RFID and RTLS technologies have proven to be effective tools for enhancing inventory management across various sectors. These technologies offer improved inventory tracking, reduced stockouts, and enhanced operational efficiency.

Retail Sector

In the retail sector, RFID technology plays a critical role in improving inventory visibility and reducing theft and inventory shrinkage. Retailers can achieve better tracking accuracy and real-time data capture, leading to reduced stockouts and enhanced customer satisfaction. RFID technology also helps fashion retailers streamline inventory management, maintain accurate stock levels, minimize losses, and provide a better shopping experience for customers.

Healthcare Industry

In the healthcare industry, RTLS technology is particularly effective for tracking both patients and high-value equipment. Efficient location monitoring and inventory management of medical equipment improve overall operational efficiency, ensuring that healthcare professionals have timely access to the necessary tools. RFID tags assist healthcare professionals by locating equipment and tracking inventory, enhancing the efficiency of healthcare facilities. The significant benefits of RTLS in healthcare settings demonstrate its potential to improve operational efficiency.

Manufacturing and Logistics

In manufacturing and logistics, RFID and RTLS technologies streamline inventory management by providing real-time data that enhances decision-making in supply chain operations. Companies in these industries can see improvements in supply chain accuracy and operational transparency after adopting these technologies. RFID technology allows real-time asset tracking systems, enhancing fleet management and streamlining operational workflows. RTLS tracks assets like vehicles and parcels in real-time, optimizing workflows and improving retail inventory management through RFID asset tracking.

Future Trends in RFID and RTLS Technologies

The future of RFID and RTLS technologies looks promising, with advancements expected to include smaller and more affordable tags, improved read ranges, and increased data storage capacities. The significant adoption of RFID technology has been greatly influenced by the boom of the Internet of Things (IoT), enhancing inventory management processes.

These technologies provide agile and responsive supply chains, reducing costs and offering actionable insights that benefit inventory management.

Integration with IoT and AI

Integrating RFID and RTLS with IoT enhances the capability to track and manage inventory in real time, providing a comprehensive overview of assets. This integration enables automated data capture and processing, minimizing manual intervention and boosting efficiency.

Combining these technologies creates actionable insights through advanced data analytics, helping businesses make informed decisions. Benefits include improved efficiency, better inventory accuracy, and optimized supply chain processes.

Advances in Tag Durability and Performance

Future RFID tags are expected to utilize advanced materials to withstand harsher environments, significantly improving their longevity. Innovations in RFID tag materials aim to enhance their performance in challenging conditions, such as extreme temperatures and high moisture levels. This durability is crucial for industries that operate in harsh environments, ensuring that the tags continue to function effectively over extended periods.

Additionally, advancements may include self-repairing capabilities, further enhancing the performance of RFID tags in adverse conditions. These innovations will help businesses maintain accurate inventory tracking capabilities without frequent replacements, thus reducing long-term costs and enhancing operational efficiency.

Enhanced Data Analytics

The convergence of RFID and RTLS with artificial intelligence (AI) and machine learning is expected to redefine data analytics and predictive insights. Advanced data analytics play a critical role in transforming raw data from these technologies into actionable insights for inventory management. This transformation enables businesses to make more informed decisions, driving efficiency and accuracy in their operations.

RFID and RTLS technologies facilitate real-time data collection to transmit data, providing a wealth of information for comprehensive analysis. These advancements will enhance decision-making processes, allowing businesses to optimize their inventory levels, reduce waste, and improve overall supply chain performance.

Why Choose AiRISTA

AiRISTA specializes in integrating RTLS and RFID technologies to enhance asset tracking and management. Their solutions provide real-time location tracking and identification, significantly improving visibility and operational efficiency. AiRISTA’s sofia RTLS software allows customers to combine data from various sensors seamlessly, offering a comprehensive overview of their assets.

By choosing AiRISTA, businesses can navigate the complexities of implementing these advanced technologies with tailored solutions that meet their specific operational goals and requirements.

Summary

RFID and RTLS technologies offer transformative benefits for inventory management, including increased accuracy, real-time tracking, and enhanced operational efficiency. While both technologies have their unique strengths and challenges, their combined use can provide a comprehensive solution for various industries. The future of these technologies looks promising, with advancements in tag durability, integration with IoT, and enhanced data analytics driving further improvements. By adopting RFID and RTLS, businesses can significantly optimize their inventory management processes and stay ahead in a competitive market.

Frequently Asked Questions

What are some common challenges in implementing RFID systems?

Implementing RFID systems often faces challenges such as high initial costs, environmental interferences like metal surfaces, and the complexities involved in integrating the system with existing operations. Addressing these issues is crucial for successful implementation.

How do RFID and RTLS improve inventory management?

RFID and RTLS enhance inventory management by offering real-time visibility into inventory levels and locations, thereby reducing stockouts and waste while optimizing order fulfillment. This leads to improved asset tracking and greater operational efficiency.

What advancements are expected in RFID and RTLS technologies?

Significant advancements in RFID and RTLS technologies are anticipated, such as the development of smaller, more affordable tags, improved read ranges, and greater data storage capacities. Additionally, these technologies are expected to integrate seamlessly with IoT and AI, enhancing tag durability and overall performance.

Why should businesses choose AiRISTA for implementing RFID and RTLS solutions?

Businesses should choose AiRISTA for their expertise in integrating RFID and RTLS solutions, ensuring effective real-time location tracking and management. Their customized offerings, such as the Sofia RTLS software, enable organizations to efficiently meet their operational objectives.