Automating the regular inspection of equipment extends the asset’s life and helps adhere to compliance.

Safety standards require the regular inspection of equipment like fire extinguishers and automated external defibrillators (AEDs). Regular maintenance is also needed for warranty compliance and extend the life of equipment including mobile equipment like fork trucks. Whether it’s public spaces like airports or private enterprises like manufacturing plants, the responsibility usually falls to facilities and maintenance teams. Traditional inspection methods have been paper based and often ad hoc. By using a Real Time Location Solution (RTLS) like AiRISTA’s, the inspection process can be simplified and automated. These systems are also effective for OSHA compliancy in terms of maintenance and location of personal safety equipment.

How does the RTLS system work?

- Placing an RTLS tag on equipment like fire extinguishers or mobile equipment provides an instantaneous location on the floorplan.

- Grouping tags by equipment category segregates inspection protocols.

- Using tags like AiRISTA’s low cost BLE tags, a button push automates confirmation that a device has been inspected. Time and location are captured in the process.

- Scheduled reports can be setup in AiRISTA’s sofia software platform to provide awareness and consistency.

Application and workflow integration

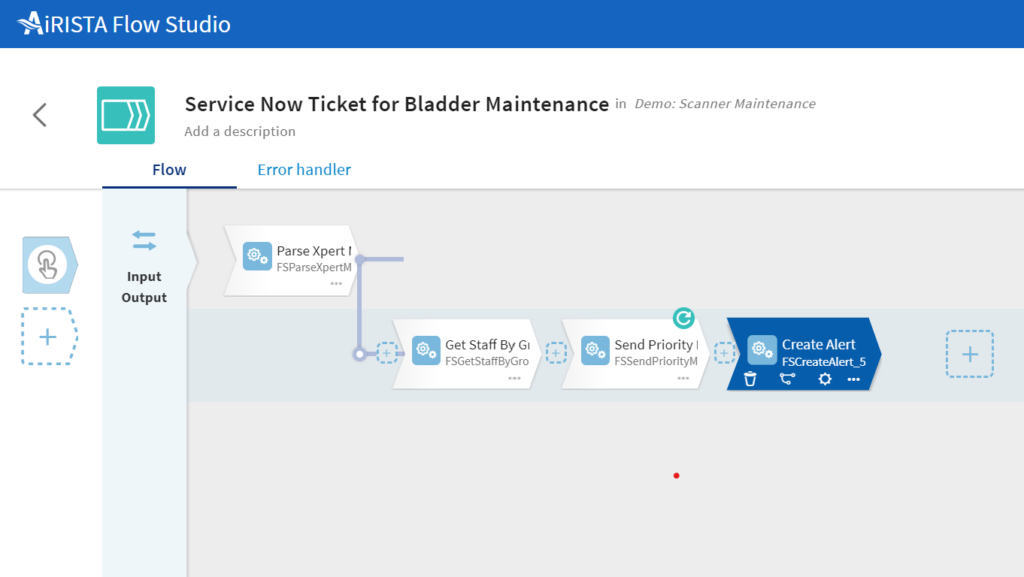

Adding to the challenge is the integration to applications and processes associated with running the plant. AiRISTA’s Flow Studio is a low-code development environment for creating workflows and integrations. Eliminating the need for custom development, Flow Studio provides a drag & drop pallet where canned code modules can be connected and logic rules inserted to create workflows. These resulting “flows” collect inputs from various sources, inspect data in real time, apply workflow rules, and distribute alerts & instructions to subscribers. As a simple example, the Flow Studio example below “listens” for a button push on a tag, alerts the appropriate staff in the area, and opens a ticket in Service Now.

RTLS solutions may already be deployed in your facility to address issues like asset tracking, staff safety, contractor accounting and even temperature monitoring. Extending the use to equipment inspection is a simple low cost addition that requires the addition of low cost BLE tags.